In our latest 'Five minute read,' our expert Louise Colley, New Business Director, Energy, Defence and Transport, shares her views on the UK's ambition to lead the world in fusion research.

Fusion energy represents the ultimate test of human ingenuity – harnessing the process that powers the sun to create safe, abundant, low-carbon energy. As the UK pursues its ambition to lead the world in fusion research, the urgency of the climate crisis and rising energy demands make its success more critical than ever.

Delivering fusion energy means replicating the power of the sun here on Earth – one of the most ambitious scientific and engineering challenges of our time which will take bold thinking, new technology and major investment in infrastructure. (See “Fusion energy explained”).

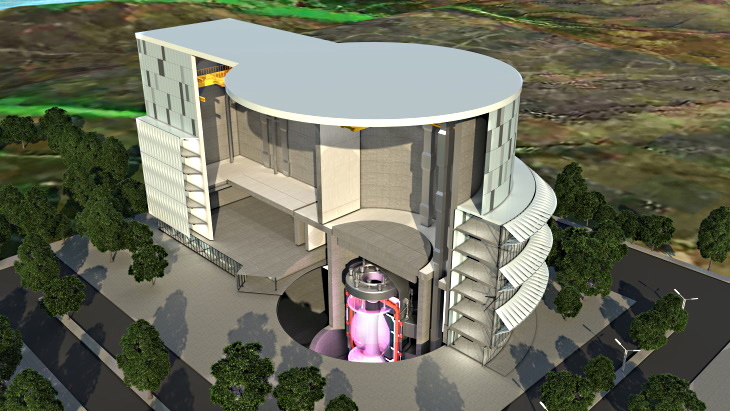

CGI of STEP prototype fusion powerplant - Image credit: UK Atomic Energy Authority

The UK is rising to that challenge, leading the way with innovative solutions including the spherical tokamak – a compact, efficient design that helps make fusion possible by trapping super-hot gas in a tight, round shape. With the world’s first fusion power plant set to connect to the grid in the 2040s, the future is within reach. But to make fusion a lasting part of our energy system, we must act now – with clear purpose and long-term vision to power generations to come.

What must the infrastructure sector and government do to effectively support the development of fusion energy?

-

Build high-performing integrated delivery teams: Commercialising such a groundbreaking, multi-faceted endeavour requires public and private organisations to work as an integrated delivery team, united by shared goals, values and behaviours that establish the UK’s commercial leadership in fusion. We must build on lessons from previous major programmes, push boundaries and shape a team capable of developing a UK fusion industry. By combining expertise, we can shape regulatory and safety frameworks, apply method-led construction to develop best-for programme solutions and create a strategy that delivers long-term economic value and leaves a lasting legacy across the UK. See our case study on “Building a high-performing integrated delivery team at Sizewell C”.

-

Take a strategic view of the UK skills base: Fusion builds on decades of fission expertise, regulatory frameworks and cross-sector capabilities. Leveraging this foundation requires long-term workforce planning, ensuring today’s expertise transitions seamlessly into future fusion capabilities. By strategically sequencing major projects now – aligning Sizewell C with expertise from Hinkley Point C, progressing into the Small Modular Reactor (SMR) programme and ultimately advancing towards fusion – we can attract, train and retain a continuous pipeline of talent, ensuring a future-ready workforce when the UK’s first fusion power plant is built. See our case study on “Taking a strategic view of training on HS2”.

-

Pioneer advanced methods for complex delivery: Fusion power plants will be among the most complex energy projects ever built, requiring precision engineering, advanced materials and new construction methods. Unlike fission, fusion involves sustaining temperatures hotter than the sun’s core within powerful magnetic fields demanding new techniques, robotic assembly and materials capable of withstanding extreme conditions. Automation, innovation and cross-sector collaboration will be key to delivering these facilities safely and efficiently. Partnerships with academia and investment in supply chain innovation must drive the development of advanced construction methods fit for fusion infrastructure. See our case study on “Pioneering innovation: collaborating for a zero-carbon future in construction”.

Fusion energy is more than just a technological breakthrough – it’s the next frontier in the UK’s clean energy revolution. Realising its potential will take decades and will require bold decisions, strategic investment and a shared commitment to building the infrastructure and workforce to bring it to life. By harnessing the expertise we have today, planning for the skills we’ll need tomorrow and forging strong partnerships across industry and government, we can position the UK at the forefront of this world-changing transformation.

Download a copy of our 'Building the fusion future' document.

Fusion energy explained: technology, infrastructure and the UK’s global role

Pioneering the future of infrastructure at HS2

Fusion uses light atomic nuclei – mainly types of hydrogen called deuterium and tritium – as fuel. Deuterium is found in large amounts in seawater, making it nearly limitless, while tritium is rarer but can be created inside the reactor using lithium, a common metal in the Earth’s crust. When these nuclei are intensely heated and pressured, they overcome their natural tendency to push away from each other and combine, or fuse, to form a heavier nucleus, releasing a significant amount of energy. This is the same reaction that powers the sun and stars. In simple terms, it produces intense heat, which can be used to generate steam and drive turbines to produce electricity, much like conventional power plants but without the carbon emissions.

Achieving fusion demands sustaining incredibly high temperatures and precisely controlled conditions – a huge technical challenge – to enable the reaction to occur and produce usable energy.

On Earth, fusion has been achieved in experimental reactors, producing energy in short bursts. Sustaining the reaction long enough and at a scale to generate more energy than is used to produce the fusion, remains a significant challenge. However, because fusion offers the promise of nearly limitless, carbon-free energy without radioactive waste, investing in finding solutions to overcome these challenges is essential.

The leading fusion technology, the ‘tokamak’, was originally developed in the Soviet Union (Russia) in the 1950s. It uses magnetic fields to confine hot plasma in a doughnut-shaped (toroidal) chamber to sustain the fusion reaction. The term tokamak is based on a Russian acronym roughly translating to toroidal (or donut-shaped) chamber with magnetic coils.

While deuterium and tritium are the most common fusion fuels and the tokamak remains the leading fusion technology worldwide, other countries are exploring alternatives including helium-3 – a rare isotope found on the Moon and potentially harvestable from space - and different reactor designs such as stellarators. Stellarators use twisted magnetic fields to contain plasma without needing the strong electric currents required by tokamaks. These designs are being pursued in Germany, Japan and the United States, while the UK concentrates on developing the spherical tokamak – which has a more compact, cored-apple shape offering improved plasma stability and efficiency compared to conventional tokamaks – for its fusion research and projects.

The UK’s STEP (Spherical Tokamak for Energy Production) programme builds on the legacy of JET (Joint European Torus) – formerly the world’s largest operational tokamak and a globally significant fusion experiment based in Oxfordshire. JET concluded operations in late 2023 after over four decades of pioneering research. STEP aims to take the next step: designing and constructing a prototype fusion power plant capable of delivering net energy gain and ultimately feeding electricity to the grid by the 2040s.

Fusion: a global race with UK leadership

Fusion energy development is a major international endeavour involving many countries and organisations. The UK is a global leader in spherical tokamak research, with facilities like the now-retired JET and the MAST Upgrade at Culham pushing the boundaries of fusion science. The MAST Upgrade is a spherical tokamak device designed to explore plasma physics and improve understanding of the conditions needed for sustained fusion. The STEP programme is a key part of the UK’s strategy to convert this research leadership into a commercial fusion power plant.

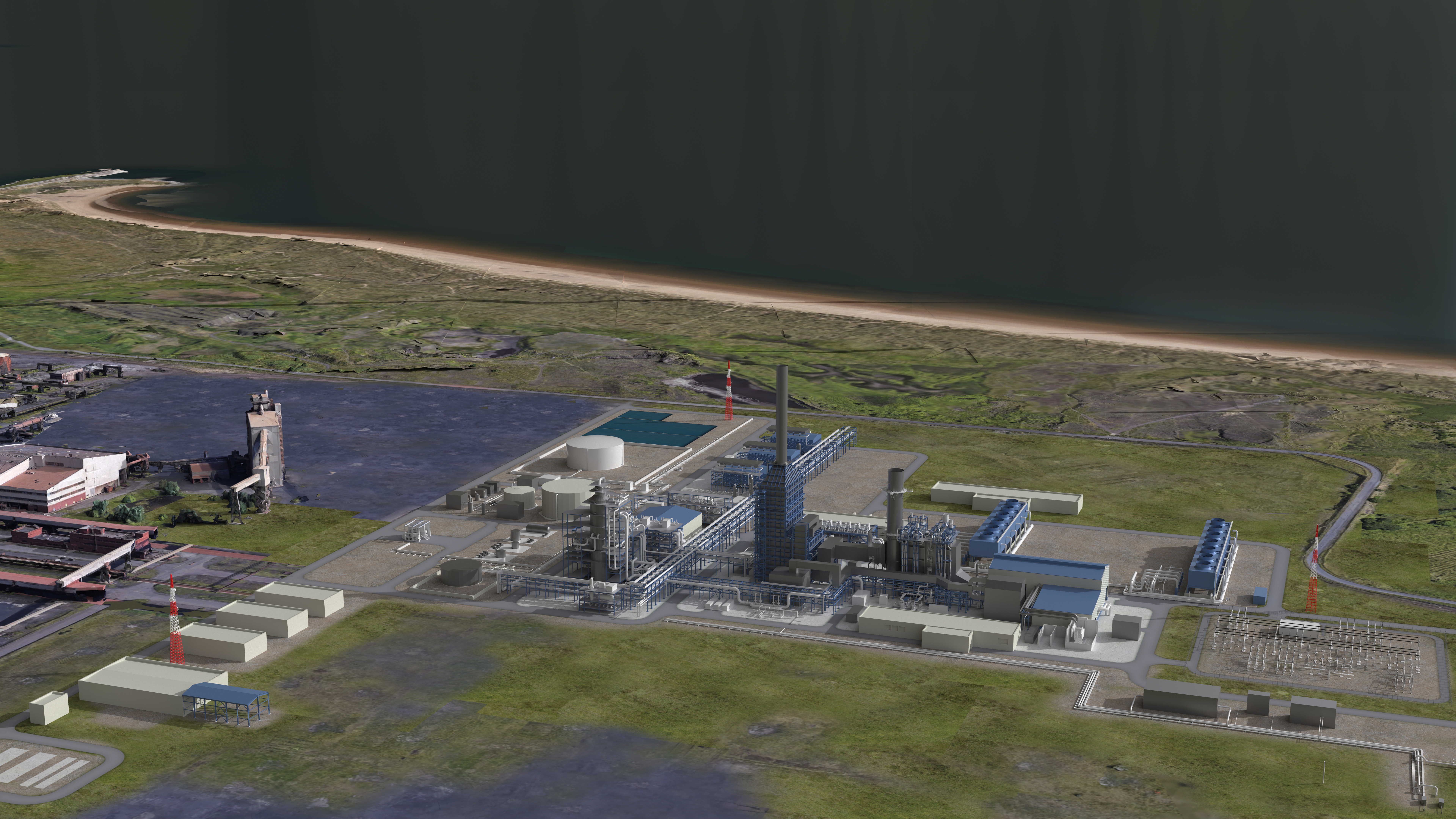

Shaping the future at Net Zero Teeside

However, fusion is also a competitive global race. Projects like ITER in France, the US’s National Ignition Facility and fusion initiatives in China, South Korea and Japan pursue different technologies and approaches. While collaboration and knowledge-sharing are common, countries are competing to be the first to achieve commercially viable fusion energy – a breakthrough with huge economic and environmental benefits.

A great deal of learning from ITER – including on complex component integration, remote maintenance and the infrastructure involved in large scale cryogenic systems – is expected to feed into the design and delivery of STEP.

That’s why Balfour Beatty is working in partnership with VINCI, the French major construction and engineering company involved in delivering major parts of the ITER facility. This collaboration positions us to bring world-class experience, cultural alignment and UK infrastructure delivery track record and international insight – helping ensure that lessons from other fusion megaprojects are available to the UK.

At the same time, STEP is not a traditional nuclear project – and the distinction is an important one. Fusion is an entirely different process from fission, with fewer safety concerns and no long-lived radioactive waste. It’s widely recognised that fusion’s unique characteristics could support a more tailored regulatory approach – one that enables innovation while maintaining safety. In that context, there is a strong case for exploring how fusion regulation can be streamlined and modernised to avoid unnecessary complexity and help accelerate delivery.

What infrastructure does fusion require?

Fusion power plants need highly specialised infrastructure, including:

- Superconducting magnets to produce strong magnetic fields that confine plasma

- Vacuum vessels capable of withstanding extreme heat and neutron radiation

- Cryogenic systems to cool magnets to near absolute zero

- Remote handling robotics to maintain and replace components in high-radiation zones

- Advanced control and diagnostics systems to monitor and stabilise plasma conditions

in real time

Developing and building this infrastructure demands innovation in precision engineering, materials science, digital integration and cutting-edge construction methods. Crucially, delivering STEP will require a robust UK supply chain capable of manufacturing and assembling these complex components, building on the expertise and capacity established in the nuclear sector. This will support not only fusion development but also broader industrial growth and high-skilled employment across the country.

STEP’s strategic importance

STEP is more than a prototype fusion plant. It is a strategic initiative to position the UK at the forefront of global fusion energy development, stimulating regional and national economic growth, developing high-tech skills and building a robust fusion supply chain. For Balfour Beatty, STEP represents an oppotunity for the UK to take part in the construction of world-first fusion infrastructure – pushing innovation in digital construction, off-site manufacturing and sustainable delivery, helping to realise fusion’s potential as a transformative energy source.

Sizewell C (SZC) is a nationally significant infrastructure project, designed to provide 3.2 gigawatts of low-carbon electricity through two UK EPR™ reactor units. To deliver the major civil works, Balfour Beatty has come together with Laing O’Rourke and Bouygues Construction and SZC itself to form the Civils Works Alliance (CWA) – an integrated delivery enterprise structured around industry best practices for improving major infrastructure delivery. The alliancing ethos builds strongly on Australian alliancing experiences and aligns with the Infrastructure Client Group’s guidance, the ICE’s ‘Project 13’ principles, the ‘pure alliance’ model and the UK government’s ‘Construction Playbook’ and ‘Transforming Performance Roadmap’.

A key pillar of our success has been early contractor involvement. Balfour Beatty led the integration of designers and CWA partners in the early phases of enabling works, earthworks and supporting infrastructure – critical elements in securing the development consent order (DCO) and advancing the UK government’s final investment decision (FID). This early engagement helped refine project costs, optimise the programme, reduce risks and unlock opportunities for efficiency.

Collaboration across disciplines – including the client, designers and supply chain – was instrumental in eliminating misalignment between design requirements and construction methodologies. Using our method-led construction approach, we matured design and construction methodologies in parallel through a structured technical lifecycle. Key outcomes included:

- Improving access arrangements and enabling concurrent working through collaborative workshops, eliminating 3.5 years from the gallery construction programme

- Reducing the scope of major complex groundworks, cutting concrete, rebar and carbon emissions, while enhancing logistics and mitigating interface risks

- Leveraging insights from our UK supply chain to proactively identify construction risks and source materials and methods that support sustainability targets, including low-carbon initiatives

As an alliance, we have pursued both transformational step changes and incremental improvements, embedding a culture of continuous learning and innovation. Our approach to intelligent replication applying lessons from Hinkley Point C – aims to make SZC safer, faster and more cost-effective. By fostering integration, collaboration and innovation, we are setting a new benchmark for nuclear construction, ensuring SZC plays a pivotal role in delivering the UK’s net-zero ambitions.

The long, secure pipeline of work provided by HS2 has enabled strategic investment in developing a robust skills base to deliver the infrastructure. As HS2 Ltd’s construction partner, Balfour Beatty VINCI (BBV) has established this industry-leading Skills Academy in partnership with the West Midlands Combined Authority – which brings together 18 local councils and enterprise partnerships – and Birmingham South & City College. The academy is training local people to fill 3,000 jobs on the project and in our supply chain, equipping them with the skills and accreditations needed for long-term careers in the industry.

Training covers a broad range of roles, from site operatives and steel fixers to environmental technicians, traffic marshals, materials testing and business support functions such as IT and document control. Candidates start with a 4-6-week training programme at the academy’s community site in Birmingham. These modules, tailored to address skills gaps in our Area North resource plan, require no prior experience enabling us to target unemployed individuals and under represented groups.

Successful candidates then move to our on-project academy facility at Kingsbury for job-specific training. This includes everything from first aid, lifting and working at height to supervisor development, early careers programmes and mental health awareness.

So far, 475 people have started training, with 108 offered paid work trials upon completion. Of these, 85% have secured long-term apprenticeships or employment with BBV or our supply partners. Together with our Operator Skills Hub – another training facility established for Area North – the BBV Skills Academy has not only helped secure sustainable employment and boost the local economy but has also addressed critical skills shortages across the programme while providing streamlined, cost-effective and integrated training for our workforce.

Balfour Beatty is proud to be at the forefront of sustainable construction through our collaboration on the Cement 2 Zero (C2Z) project. Partnering with the University of Cambridge, AtkinsRéalis, Tarmac and the Materials Processing Institute, we are trialling Cambridge Electric Cement (CEC) – the world’s first zero-emission Portland cement – at an industrial scale. This innovative process repurposes construction waste within steel recycling, creating a circular solution that eliminates emissions from traditional cement production.

Backed by £6.5 million in UK Research and Innovation funding, the two-year C2Z trial is rigorously testing each stage of production to ensure this breakthrough material can be seamlessly integrated into real-world construction. Early pilot trials have already demonstrated its potential and with large-scale 75,000 tonne trials underway, we are moving closer to a fully scalable, sustainable alternative to conventional cement.

At Balfour Beatty, we are not just reducing our industry’s carbon footprint – we are shaping its future. Our commitment to innovation and R&D extends beyond our own projects, driving progress that raises the bar for the entire sector. By championing solutions like CEC, we are accelerating the transition to net zero and ensuring the benefits of innovation are shared across the industry. This is a step towards a smarter, greener and more responsible built environment.